People frequently assume they have to buy a piece of software to implement an earned value management system (EVMS). Install the EVMS software and Presto! You are now compliant with the EIA-748 Standard for EVMS 32 guidelines.

Is that a true statement? The answer is a resounding No!

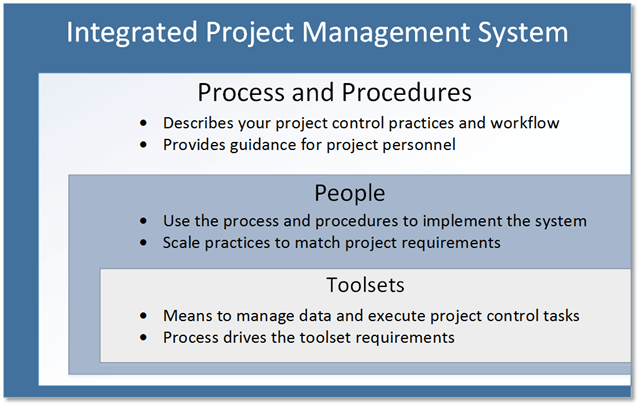

The operative word is “system”. That means your project management process and procedures. It also includes how your project personnel implement that process and follow established procedures. Toolsets just facilitate project personnel to execute their project control tasks. The following image illustrates this.

A Better Question

A better question to ask is whether your project management system incorporates practices that support earned value management (EVM). “EVM” is an industry standard label that makes it easy to identify a specific set of project control best practices useful for objectively determining progress for discrete, measurable work effort. You use EVM practices when it makes sense for the scope of work. You can also scale EVM practices to fit a project’s complexity, duration, risk levels, and contractual requirements.

When customers put out a request for proposal (RFP), they may include the requirement to use an EVMS. Citing the EIA-748 EVMS Standard in a contract makes it easier for the customer to define their project control expectations. The EIA-748 is an accepted industry standard that defines a basic set of guidelines and common terminology for project performance measurement. Combined with other industry documents[1] and government agency requirements[2], it provides a common foundation for expected integrated project management input and outputs. These include performance measurement metrics commonly associated with earned value management and specific report formats or data deliverables a government customer expects. Commercial off the shelf (COTS) software vendors use these references to develop their offerings. Your internal IT resources could use the same references should you wish to build your own tools.

A customer referencing an industry standard benefits all contractors. Why? It levels the playing field; it also provides a common understanding of the basic requirements to support EVM practices. For example, it documents an agreed upon best practice is to create a network schedule useful for identifying the project activities, sequence of work, and what resources are required when.

Even with agreement on the basics, there are sometimes passionate discussions about specific nuances when applying best practices. For example, the use of schedule margin and handling level of effort activities are frequently discussion topics related to scheduling practices. These discussions are essential and a useful exchange to further best practices. They cause people to think through what they are doing and determine whether certain practices help or hinder their ability to manage their work.

This is where “system” comes into play. You define your project management system. You determine how you incorporate EVM practices into your system regardless if you use the EVM label or not. It may make more sense, and sometimes is preferable, to call it your Project Management System Description or Project Control System Description instead of an Earned Value Management System Description. You determine how you would like your project personnel to apply project management best practices appropriate for your business environment. Write your process and procedures for the project personnel who will be using them. Make it easy for them to understand the process flow and follow preferred practices.

Process and Procedures Come First

Your project management process and procedures take precedence over any software toolset. This includes any practices needed to support EVM.

Software tools can definitely help you create quality schedule and cost data – provided your project personnel have a useful process in place to follow. This is particularly true as the size of the project increases. Tools can make it easier to integrate the data, calculate EVM metrics, and produce EVM reports listed as contract deliverables. Software vendors are more than happy to sell you tools specifically designed to support typical EVM artifacts. You could just as easily use a decent scheduling tool and spreadsheet to support EVM. For all their benefits, software tools are not a substitute for processes and procedures.

A government entity such as the Defense Contract Management Agency (DCMA) coming in to look at your project management system assesses the project control process and procedures you are following. They also look at how your project personnel are applying that system on a given project using your toolsets of choice. Are they following your documented process? That helps them determine whether your system supports the EIA-748 guidelines in accordance with their interpretation guide to deem your system “validated”. They will ask for your schedule and cost data as part of their standard data call. They will also assess the quality of your data, but that is only one factor. Data quality is often a clear indicator whether you have useful processes and procedures in place for project personnel to manage the work effort effectively.

Mapping to the EVMS Standard Guidelines

Another thing to consider: create a map of your project control process and typical project control outputs to the EVMS Standard guidelines. This helps demonstrate to DCMA or other external parties your process supports the guideline requirements. DCMA uses a detailed checklist organized by the guidelines. Your map makes it easier for them to identify where in your process documentation you discuss the topics of interest to them. You can also use this map in response to requests for proposal when an EVMS or EVM reporting is an expected contractual requirement.

Need help organizing your processes and procedures to gain a better understanding of where you can incorporate EVM best practices? Give us a call today.

[1] An example is the NDIA Integrated Program Management Division (IPMD) EVMS Intent Guide to the EIA Standard for EVMS available on the Division’s Guides and Resources web page that describes the management value, intent, typical attributes, and typical outputs associated with each guideline.

[2] Examples include the DoD EVMS Interpretation Guide (EVMSIG) and Data Item Descriptions (DIDs) such as the Integrated Program Management Report (IPMR), DI-MGMT-81861A found on the OSD PARCA EVM Policies and Guidance web page.